This Excel spreadsheet can be used to calculate the frictional pressure drop or the gas flow rate or the required minimum pipe diameter. Pressure Vessel Nozzle Design Spreadsheet Calculator Design calculations for pressure vessel nozzle per.

Horizontal Retention Vessel Pressure Vessel Engineering

14Test Press P 13 MR 30 13 1mTp 39.

. Design of dish under external pressure. ALLOWABLE STRESS REFERENCE Calculation Reference API 650 Oil Tank Design Pressure Vessel Design Calculation Preview. I IV VI VII X XII -- Boilers And Pressure Vessels Related Offerings.

Learn From Industrys Top Technical Experts. Ad Designs Manufactures A Broad Range Of Pressure Vessels Reactors. Sign Up for One of Our Courses.

SHELL DESIGN THICKNESS CALCULATION BOTTOM PLATE ANNULAR BOTTOM PLATE DESIGN INTERMEDIATE WIND GIRDER DESIGN WIND DESIGN ANCHOR BOLT CALCULATION. All software provided As-Is with no warranty expressed or. External Design Pressure Diameter of ShellHead Design Temperature Allowable Stress of Shell Joint Efficiency Corrosion Allowance Formula used Result t.

UG-27c12 This sheet will not calculate thick walled vessels Treq 05Do2 Use the Weld Efficiency program to calculate El and Ec. Licensed under the. Designed and built with by Erik Fong.

Such failure of pressure vessels under uniform external pressure is called non-symmetric bifurcation buckling or shell instability. Nasrul M Asral namasral Submitted On. First a design is selected with all variables included and then the design is checked to verify if it is adequate.

External pressure calculation The External pressure calculation divided into two types of calculation due to the vessel s part. UG-37 Appendix 1-10 1-7 and div 2. At Large end OD.

L Unbraced length of column in inches. 2 HP 2varb314varGmP contact load 20135314121250201 0. The pipe information is used to find the inner area and relative roughness of the piping.

Psi mm F psi mm. 1 Cubic Foot CF approx 1000 BTUs 1 CFH 1 MBH. Download File - Lifting Lug Design Spreadsheet.

Design of dish under internal pressure. 8 hours agoPipe rack width height length calculations 2. 216800 14000 1710000 100 300.

If 120 Lr 1317 then Cma 1-Lr23470033000FsY16L200r When Lr 1317 then Cma 149000000YLr216-Lr200 Where. P D Temp S E CA. 12 13Hydro Test UG-99bpressure measured at top of vessel rounded up.

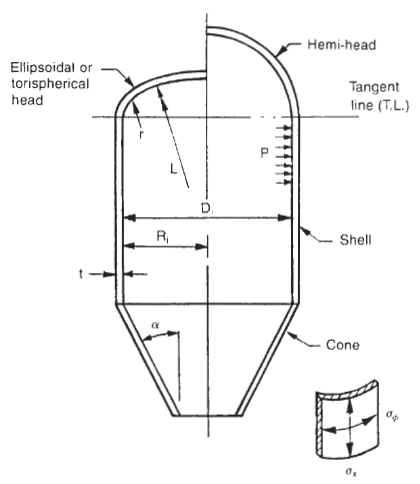

P design internal pressure psi P a allowable external pressure psi P s design external pressure psi R s outside radius of spheres and hemispheres t thickness of cylinder head or conical section in. 1-The head 2-The shell First. R Least radius of gyration of column in inches.

Calculations per ASME code include. 4629 90 x 500 x 00362 30. If a 500 inch diameter vessel is 90 filled with a fluid of density 00362lbin³ and an over-pressure of 30psi is applied at the surface of the liquid the maximum pressure at the top of the vessel will be 30psi whilst the maximum pressure at its base will be 4629psi.

Rectangular Tank Design with Horizontal Stiffening. Standard Custom Designs including Quick-Open ASME available Engineer Support. 12 hours agoDiameter Sizing Calculator found at Gas Pipe Sizing Duct Calculator Elite.

Design of Pressure Vessel Design of Cone under Internal External Pressure Material MATL SA 515 Gr60 Design Internal Pressure Pi 1733655 psi 12166 kg cm² Design External Pressure Pe 1425 psi 1 kg cm² Design Temperature Temp 401. When Maximum Allowable Working Pressure or MAWP calculation is not done then we used Design pressure in place of MAWP. The geometry of the equipment is the critical factor rather than material strength.

Up to 24 cash back Tools for Design Estimation of Pressure Vessels and Shell Tube Heat Exchanger. 398 D Sample of Pressure Vessel Design Data Sheets d Reinforcementloadcarriedbyreinforcingplate 828002846027800 26540lb. At Small end Half Apex Angle Knuckle Radius Flare radius.

At Large end ID. Designing vessels for external pressure is an iterative procedure. Report Pressure Vessel Design-Excel-sheet-basic-designing-non-critical-Pxls Please fill this form we will try to respond as soon as possible.

90000. If inadequate the procedure is repeated until an acceptable design is reached. Pressure Vessel Nozzle with Repad Design Tool per.

Basic Pressure Vessel Stressxls. 1 He 0785varG2Pe end load external pressure 07851212520 0. Joint Efficiency Radiography Corrosion Allowance Polishing Allowance Thinning Allowance Type of Cone Provided Thickness OD.

PRESSURE VESSEL SHELLS MATERIALS FUEL CELL CARS A fuel cell. Design of shell under internal pressure. END OF THIS WORKSHEET GMs Fuel Cell Car BASIC STEAM ENGINE BOILER Shell Longitudinal stress S L Shell Circumferential stress S C Spherical head stress S H PR 2 t Design shell thickness ts MATH TOOLS LINKS Actual Thin Wall Pressure Vessel Stress SPREAD SHEET METHODS.

A Loadtobecarriedbyattachedreinforcement 8280028460 54340lb. MinPint1Pint2 maximum allowed design pressure This sheet cannot be used to check for allowable exterior pressure loads. Allowable compression in PSI.

Crown radius of torispherical heads in. Stress at Design Temp. 4 HDe pi4 B2 Pe end load external pressure PI4 113762 0 0.

VESSEL CALCULATION Account 207461340. At Small end ID. Design of cylindrical shell under external pressure.

Design new steam pipes correctly on pressure drop and velocity methods. A designer always find of. Material impurity and initial out of circularity of the cylinder further reduces the resistance to external pressure and hence decreases the critical buckling load.

That can be concluded without knowing basic laws of strength of material. 6 HTe He - HDe face load external 0 - 0 0. Xls Pressure Vessel Calculations Asme Section Viii Division I Basincli Kap Tasarim Hesaplamalari Ahmet Oven Academia Edu SHELL DESIGN THICKNESS CALCULATION BOTTOM PLATE ANNULAR BOTTOM PLATE DESIGN INTERMEDIATE WIND GIRDER DESIGN WIND DESIGN ANCHOR BOLT CALCULATION.

5 HT H - HD face load 23191 - 20425 2766. - Vessel Supports Spreadsheet As per Pressure Vessel Design Manual-Dennis Moss. Assume a thichess if one is not already determined.

Calculating emissions is a multi-step process. 5 HT H - HD face load 23191 - 20425 2766. Treq in Treq.

T o equivalent thickness of cone in. Design of cone under internal and external pressure. THICKNESS OF SHELLS UNDER INTERNAL PRESSURE Cylindrical Shells-Circumferential StressLongi P R Do No Equipment Internal design Inside radius Outside Diameter pressure 1 0 2 3 Circumferential StressLongitudinal Joints t S E t Shell Thickness Maxallowable Joint minumum required Corrosion stress efficiency thickness of shell 085 DIV0.

PD 2 SE 06 P PD 2 SE 06 P 195691. Material Design Internal Pressure Design External Pressure Design Temperature All.

Hand Calculations Pressure Vessel Engineering

Steam Boiler Design Calculation Xls Click Visit And Get More Ideas Steam Boiler Boiler Boiler Engineer

Pressure Vessel External Pressure Calculations

External Pressure Pressure Vessel Engineering

Hand Calculations Pressure Vessel Engineering

Shell Thickness Calculation Under External Pressure In Pressure Vessels Youtube

Manual Calculation For Designing Pressure Using Asme Code Download Scientific Diagram

0 comments

Post a Comment